...

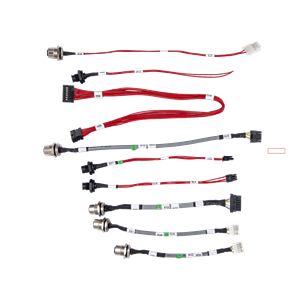

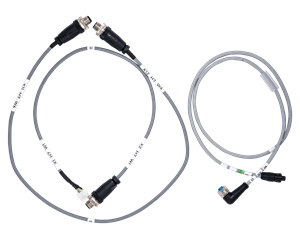

Cable Assembly &

Wire Harness

Manufacturer

In india

...

Leading Wire Harness Manufacturers | Custom Cable Assembly Solutions Tailored for Your Needs

Partner with top-rated custom wire harness manufacturers providing reliable, high-quality solutions for diverse industries, including automotive, industrial automation, and telecommunications.

Why Partner with Us?

At Jayshree Instruments, we specialize in delivering tailored wire harness solutions designed to meet the unique demands of our clients. Whether you’re in the automotive or industrial automation sector, our team of expert engineers ensures top-quality custom wire harnesses that meet industry standards.

How We Work

From Concept to Completion

01

Consultation & Design

02

Prototyping

03

Procurement

04

Manufacturing

05

Quality Control

06

Assembly & Packaging

07

Logistics & Delivery

Why Choose Us

One stop fabrication and assembly.

Parts sourcing

Comprehensive quality assurance

Professional engineering team

High efficiency with competitive price ranges

Certification

Jayshree Instruments is certificated with the ISO 9001:2015, ISO 14001, UL

and RoHS listed, we are always committed to stringent quality control.

Get A Quote Now

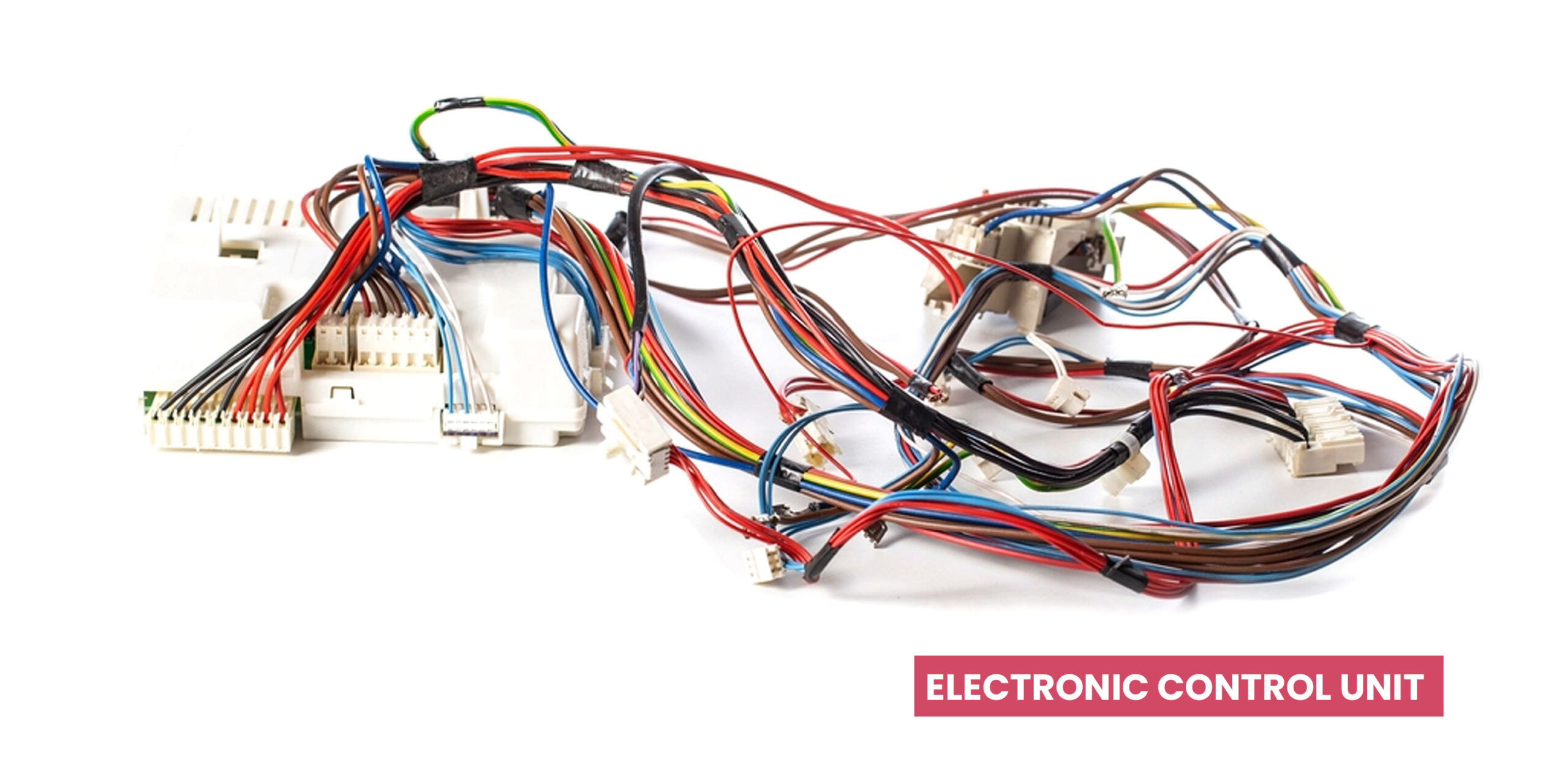

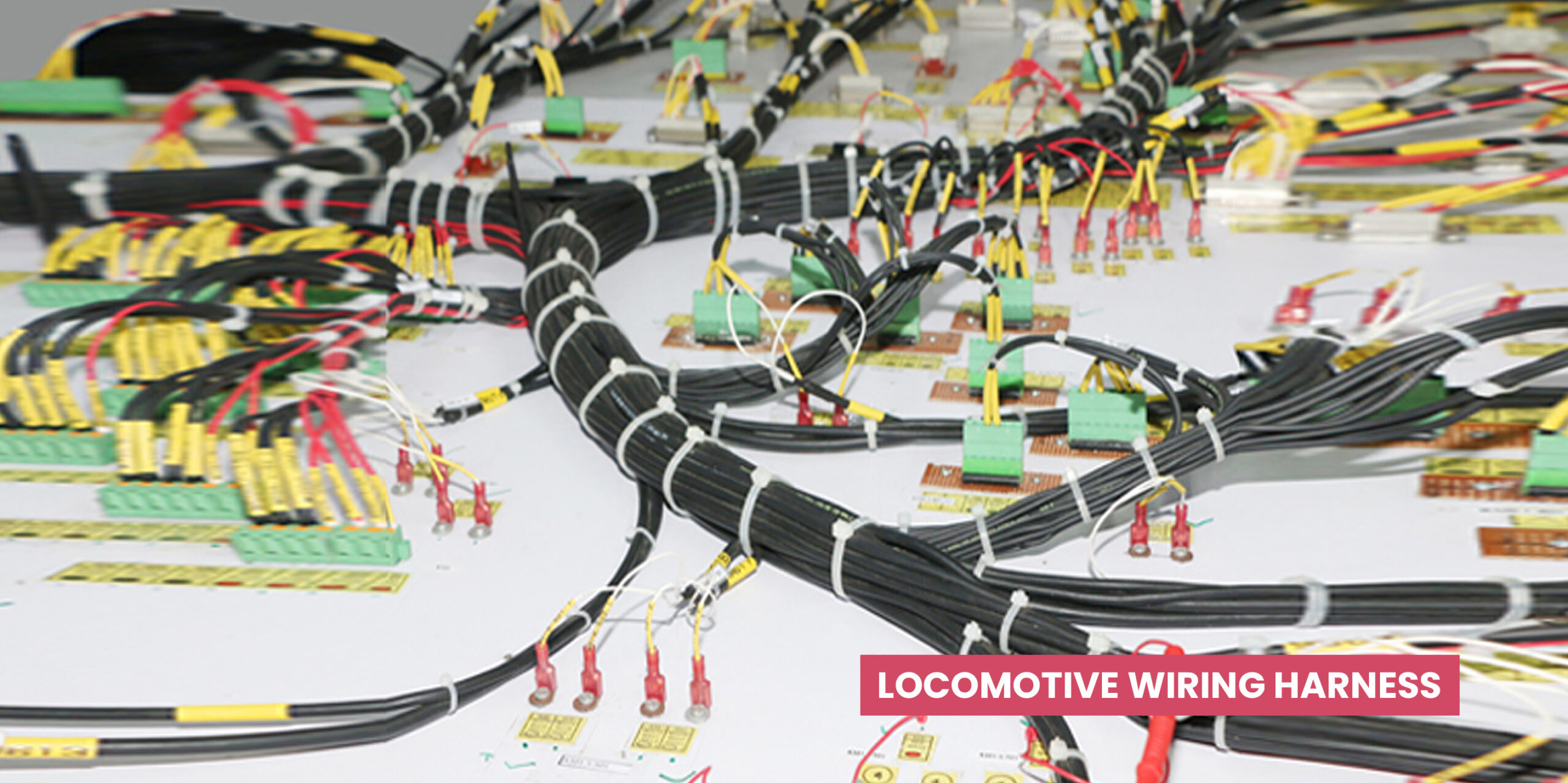

Industries We Serve with Custom Wire Harness Solutions

Consumer Electronics

Industrial Electronics

Industrial Automation

Renewable Energy

Tele Communication

Medical Devices

Automotive Electronics

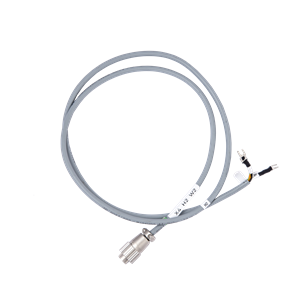

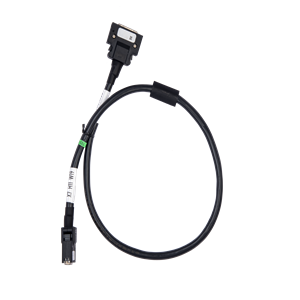

CUSTOM CABLE ASSEMBLY FEATURES

Jayshree Instruments offer custom cable assembly design expertise. We have manufactured cable assemblies to fit a vast field of flexural requirements. Our experience and abilities help us efficiently create custom cable assembly for a variety of industries.

CONDUCTOR SIZES

We can eject conductors of different gauge sizes and also can combine different sized gauge to create a mixed gauge cable. The sizes are available ranging between 34 awg to 12 awg.

CONDUCTOR COLORS

Jayshree Instruments is a well-known cable assembly manufacturer and we can make cable with numerous conductors. Especially to keep a track of conductors we can make use of different colors, different stripes, text, dashes and more to make sure the right conductor is used for the right spot.

STRANDING SIZES

Conductors can be made with stranding which is as small as 0.0002 inches, which is great for hi-flex and supply cables. Stranding can be of different materials like care copper, tinned stranding, tinned conductor and more. They can also be make of metals like silver to get better conductivity

CONDUCTOR INSULATION

Conductor insulation is the first protection layer in any cable for which we use a wide range of insulations from basic PVC, PE or PP. The stiffness and softness of each material may differ

FILLERS

To make a cable give the best results, it is important to include fillers in the electric cable. Materials like basic cotton, nylon and Kevlar are used usually. All materials are custom matched as per the requirement of the application to give the best outcome.

WRAPS AND SHIELDS

A cable’s conductor needs to be wrapped or shielded generally. High flex cables require a soft barrier between the conductors and outer jacket to avoid abrasion. Numerous electric cables require shielding to secure it from RFI or EMI interference. Materials like fleece, cotton and aluminized Mylar are used to help the cable match the operating environment. It is usually wrapped with spiral overwrap.

JACKET MATERIALS

The final barrier between the environment and the inside of the electric cable is usually its jacket. The final covering is used like an insulator, a shield and protective cover. To create a cable we can utilize materials like PVC or natural rubber, Teflon or Silicone.

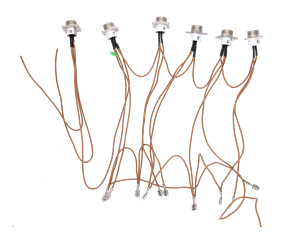

Different TYPES OF WIRE HARNESS TERMINALS

Wire Terminals are available in a variety of shapes and sizes. This depends on the size of wire and screw. Here several types of terminals are used for Wire Harness Manufacturing.

RING TERMINALS

A ring terminal has a round-end helping a screw or stud to be attached. They are also commonly known as ring connectors which are available in various sizes. It is necessary that the ring terminal is compatible with the wire gauge and the size of stud. They are usually soldered or crimped to the wire and are available insulated or non-insulated.

SPADE TERMINALS

Due to the shape of the terminal, Spade terminals are also commonly known as spade connectors or fork terminals. It is available in various sizes depending on the gauge of the wire and size of the stud. For efficient attachment and screw removal, the open-ended spade terminal is very useful and more importantly for wire harness projects where the space is a concern for installation. Spade terminals are available in insulated as well as non-insulated.

HOOK TERMINALS

Hook terminals are similar to spade terminals which are convenient to use with an open end. They are available in insulated as well as non-insulated. They provide a simple yet durable connection for different kinds of projects.

QUICK-DISCONNECT TERMINALS

A quick-disconnect terminal offers an easy connect and disconnect with two wires along with convenient and reliable usage. They are usually used in consumer products, auto products and other industrial products. The products using quick-disconnect can be insulated and as well non-insulated. This terminal assures stable and durable connection.

BULLET TERMINALS

Bullet terminals assure an easy, secure and reliable connection. It is easy to disconnect as well. They also connect to the open-ended female connectors as well as male connectors providing a high-quality connection. Which is why connection with bullet terminals helps avoiding corrosion and other harmful materials to get in the wire harness.

BUTT TERMINALS

A Butt Terminals terminates or connects single or multiple wires. They help avoid abrasion and cutting. They offer extra protection to keep the moisture, corrosion and other negative elements away. You just need to install each wire on the open end of the connector, and then crimp the terminal from both the ends to secure the connection.

FERRULE TERMINALS

Ferrule terminals are utilized in numerous applications for fastening, sealing, joining or reinforcing wires to each other.

FLAGGED TERMINALS

Flagged terminals are also known as Flag connectors ensuring secure and convenient connection. They work well in tight spaces and also when a quick-disconnect is too large. Flagged terminals assure easy connection and disconnection

Wires are available in different types as well like stranded, flexible ground braid, ribbon cable – Gray, THHN – solid, THHN – stranded. These wires are used as per certain specifications

FAQ'S

What is the difference between a cable assembly and a wiring harness?

Cable harness conducts power and transmits information in a uniform way. Engineers and designers must explain and overcome electrical issues regularly, especially during the electronic product research and development stage to bring a product to the market successfully.

One of the most important parts of this includes a challenge which has a custom design for each products electronic part and step by step cable harness manufacturing procedure to finish the assembly. In this step, designers select harness components and decide on other use specifications.

Cable assembly can be used for what kinds of applications?

Cable Assemblies are used with almost every other electrical system. Jayshree Instruments focuses on manufacturing high-quality cable assembly components in different industries like medical, telecommunications, industrial, military and others. The design capabilities are different depending on the kind of industry.

We can help you design the perfect set-up for any application as per your requirement. Our experienced and skilled engineers make sure to satisfy all the complicated requirements of the clients with products which can be utilized for the long term. Jayshree Instruments also serves customized designs.

Why do cable assemblies require filters?

Cable assemblies consist of filters which can be easily overlooked for their simplicity. But actually filters provide numerous important support functions to the cable assembly.

Generally custom cable assembly needs using wires with a variety of diameters. Filters play a major role, by helping them maintain the round shape of the cable. It helps to keep uniform appearance and offers support as well.

Does Jayshree Instruments create a custom prototype for the required cable assembly?

Jayshree Instruments provides high-quality internal prototype PCB assembly services so that you may test your product before deciding to invest in its manufacture. Our primary area of competence is offering cutting-edge, dependable electronic manufacturing services. We are aware of how important prototyping services are.

We are an electrical contract manufacturer, thus we are familiar with the difficulties faced during the prototype stage. Our goal is to provide you with a complete electronic manufacturing solution and market-ready your product.