You have an idea for a new electrical product, or even better: you have a layout plan for your solution, and all you need to launch the product is a trustworthy partner who can turn your vision into an actual product.

As there are many players in the electronics manufacturing service industry, it can be a daunting task to find a suitable manufacturer for you. You definitely would want your product to be developed successfully and efficiently but wonder what criteria should you look up to select the best EMS partner to work with.

To make the best and most educated decision possible, read on to understand the below characteristics that are essential in an electronic manufacturing service provider.

Industry experience

To begin with, it is always to your best advantage to select a contract electronic manufacturing business with substantial experience in the electronics industry. Well-established companies can be relied on to supply high-quality products, and they will take care of each board they develop and manufacture.

The more experience a company has in electronics manufacturing, the better.

Don’t be reluctant to ask how long your potential electronic manufacturer has been in business. It will help you decide whether they’ve worked on projects that are similar to yours.

Design Expertise

In addition to offering clients an electronics production solution, your outsourcing partner should be able to support you throughout your design process. Whether you’re beginning from scratch or just need a second pair of eyes to look over your current specifications.

Your outsourcing associate should be capable of collaborating with you at any stage of the design process, whether that is creating preliminary sketches or revising your most recent prototype.

An ideal electronic manufacturer should be able to help you optimize your design process and make your collaboration as fruitful as feasible.

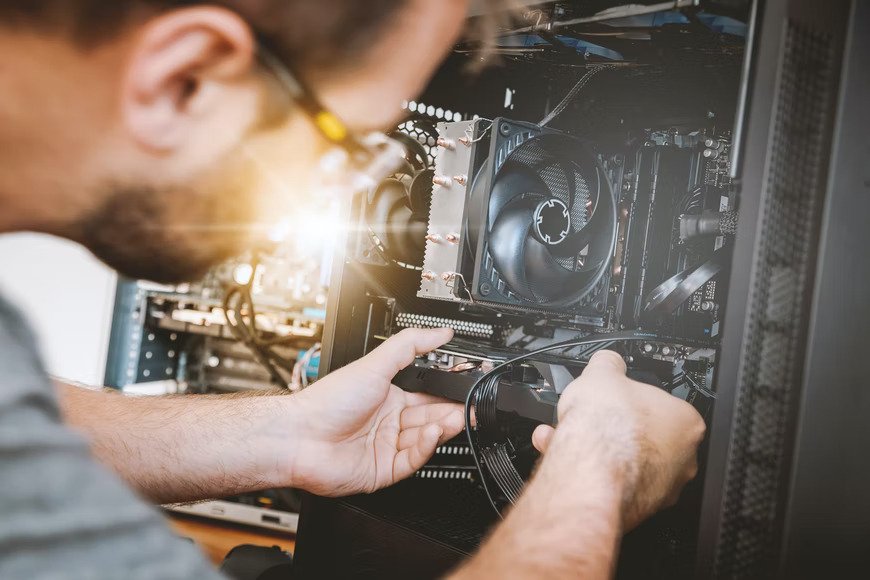

Cutting-edge Technology

Technology is evolving every day. If you are not technologically advanced – then your EMS partner should be. They should be well-equipped and know how to implement state-of-the-art technology. Do check about the machinery, tools, and equipment used by your prospective electronics manufacturing service provider.

Working with an EMS provider who utilizes cutting-edge technology will give you a competitive advantage. Do not be reluctant to enquire about the technology and equipment used by your prospective electronic manufacturing service. It is vital to look for a partner invested in surface mount technology if your requirement is high-volume production.

Industry compliance

Do not work with a contract manufacturing company that does not abide by industry best practices.

Electronic manufacturing services must adhere to regulatory requirements. They must follow industry norms and regulations as they affect every stage of the manufacturing process as well as the final product.

In addition to adhering to different industry rules and regulations, your partner company should also follow your precise production requirements.

Quality Assurance and Quality Control

A good EMS partner should not overlook and have a strict quality control system.

The worst-case scenario is if you make defective devices that don’t work or lead to more grave situations such as client injury. Electronics of any kind can catch fire or melt if sufficient quality control is not implemented.

When selecting an EMS partner, ensure that they have a track record of delivering quality items on schedule and without errors. The electronic manufacturer should follow both quality control and quality assurance. Quality Assurance is process-oriented, whereas Quality Control is product-oriented. A QA system will result in speedier turnaround times and no product recalls and it will also keep your budget in check.

Supply Chain Management

It’s essential to inquire about your EMS provider’s supply chain and global production techniques.

Your EMS partner must have a supply chain management system for production to run effectively. In the absence of supply chain management, you and your EMS partner may face the risk of spending time looking for numerous factors of your product.

Inquire your EMS partner about the type of software they use for supply chain management and their knowledge about global manufacturing norms.

Incorporates Product Testing

Once the production is complete, it does not mean that the product is ready to sell in the market. You need to follow thorough product testing before proceeding with its distribution.

Identifying any faults during the testing process before your product goes to market may cost you more in initial modifications and reproduction – but it will save your time and reputation in the long run.

Test each product component to rule out any errors or shortcomings without spending a lot of time and money.

Our manufacturing and electronic engineering professionals adhere to IPC standards, resulting in the development of high-quality, dependable components.

The Final Note

With so many options for electronic manufacturing services in India, choosing the right one for your business can be a challenging task. As previously stated, you must first analyze and evaluate your company’s specific requirements.

After you’ve determined your needs, begin researching and evaluating EMS providers that can meet them.

If you are looking for a company that takes pride in its ability to supply you with complete electronic manufacturing services of the highest quality, go no further than Jayshree Instruments. Contact us today to know more about collaborating with us on your next project.

Recent Comments