One of the most complex and important part of an electronic device is the cable assembly. Why are these cables important? The cables help in protecting the wire from any hazardous environmental factors & also directs the electricity to reach the final destination by providing electricity paths.

So when two or more wires are bonded together to form a single cable, it is known as Custom Cable Assembly process.These bunch of organized wires is also sometimes referred to as cable harness of wiring looms. These cable wires come in different colours, sizes & lengths, & all this depends on the specifications given by the supplier to the manufacturer in consideration to the application used by the electronic device.

A proper cable assembly process depends on several factors, a cable assembly manufacturerneeds to consider, taking in view the electrical & mechanical performance of the device.

Important Points you need to know about Cable Assembly Design

The most important purpose of the cable assembly is to give an easy way of connecting & disconnecting any equipment or systems. And to make it a perfect one, it’s an important to take into consideration many factors affecting the design of a cable assembly.

The design should be cost-effective and also helps to develop the overall integrity of the system.

Let’s check the below points which should be considered for a successful designing of a cable assembly.

-

Material of the Conductor

It is very important to check the material of the conductor you are using, whether it is a good supporter of electricity or not. Many manufacturers use copper as this metal is one of the best conductor of electricity and used for many wires during the cable assembly process.But you can also choose from the different versions of copper available in the market which can be considered to use like copper alloys & standard copper. Also, there are different options of plating that needs to be taken care of. So it is indeed a lengthy process to be carried out.

-

Choose the Base Material- Copper Alloy or Copper

As said above, copper is the first & foremost choice for performing as a base for wires because of its great conductivity, cost effectiveness & formability. So, copper alloy or coppers are by default used as conductors for all the cables. Mainly copper alloy is used for space applications & small wires, as they have a good tensile strength which prevents the wire to break. Other metals which are considered, especially in the medial field are stainless steel & platinum.

-

Deciding the Plating Material

Why a cable wire needs plating? There are basically few strong reasons to add plating, which are as below:

- To improve the frequency performance;

- To avoid corrosion & oxidation;

- To smoothen the termination process be it crimp or solid;

Generally, three plating materials are generally considered:

- Nickel: This material is used for applications relating to high temperatures as the temperature rating for nickel is around 250° C. But nickel is expensive and also not good for solder ability & terminations.

- Tin: This is used for applications that are low in cost &tin forms a protective layer on the copper, preventing the copper from getting oxidized. The only disadvantage of tin is the soldering issues because the material is poor high frequency one as the tin whiskers.

- Silver: Silver is a good conductivity for high frequency applications & the biggest advantage is its solder ability.

-

Solid wires or stranded wires

One of the important step is to decide whether to use stranded wires or solid wires. Solid wires are low in resistance & are a bit cheaper. But, generally solid wires are used in case of high speed applications. The reason for the same is the construction is symmetrical & concentric & so solid wires provide a low skew.

Whereas, stranded wires have a great amount of flexibility, better crimp ability & a good flex life. Seven strands are generally used, & the application that requires more flexibility, for that, nineteen strand versions are used.

-

Insulation Material

The material surrounding the conductor wires is known as the insulation material. The main goal of this wires is to prevent any short circuits, avoid any mechanical stress & the dielectric breakdown of the wires from the nearby electrical signals.

There are many factors that affect the selection of the insulation material:

- Temperature Range- this is one of the important factors as this may result to the usability & process ability of the wires in hazardous environment. During heated temperatures, the material should not melt or shrink & even the process ability is important as the insulation material should not melt if soldered anytime;

- Flexibility: the flexibility of the insulation material also plays an important. The flexibility of the material is majorly influence by the jacket & braid material;

- Dielectric constant: This factor is only important in case of high-speed applications. Dielectric constant affects the loss & impedance through the cable;

- Outgassing: There is a process of releasing gas from the material, this is known as outgassing. When the space is low, outgassing materials are used, which also helps in maintaining a pollution free environment;

- Flammability: check how good the material is flammable. The materials that have good flammable feature are preferred more, as these materials don’t release much toxins in case of fire.

There are mainly three categories of materials used for Insulation, which are mainly Polyolefin, Teflon & PVC. All these materials have their own advantages & disadvantages depending on the applications.

-

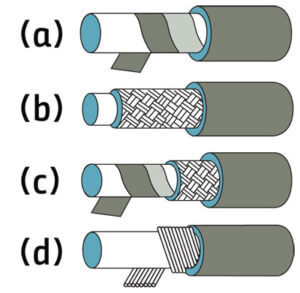

Cable Shielding Options

The conductive material surrounding the wire inside the cable is known as cable shield. The main purpose of this shield is noise prevention from the surrounding environment & the signals within the cable. Generally, there are two types of shields one can find within the cable – an overall shield & an individual shield.

Below mentioned are some of the shielding options:

- Braided Shields: This type of shielding isflexible; resistance is low & have good flex life. The braid coverage is generally 80-95% & so it’s not suitable for high frequency applications.

- Foil Shields: Foil shield is very thin and can be effective up to 100% mostly, so it tends to have an excellent shielding. But the negative side is the high resistance & poor flex life.

- Foil & Braided Shielding: this is one of the great combinations & the best choice for high frequency applications. This is because it combines the advantages it meets the effective feature of the foil shielding & the flex life feature of the braid shielding.

- Serve shields are best suited for low frequency applications and is a box of many wires wrapped around the wires in a spiral form. But this type of shielding creates a coil effect causing to signals above 1 MHz

-

Cable Jacket

A non-conductive materials surrounding the bunch of wire is known as cable jacket. The main reason to have a cable jacket is protection from the external factors – like flames, moisture & chemicals, this will further help to improve the appearance of the harness wire. Like selecting a cable jacket, there are several factors to be considered – Maximum temperature, outgassing, ruggedness, flammability, &Autoclavability.

Mainly four different kind of materials are considered for the cable jacket- PVC, Silicone, Teflon &Polyurethane.

In conclusion, it is understandable that cables form a very important part in deigning of any kind of assembly. So it is very necessary to select the materials & shielding ways, after looking at the needs & specifications of the applications. Cable assembly processcan only be successful if efficient designers are appointed for this process and they should be aware of all the mechanical & electrical challenges that a cable can face.

Recent Comments